In this week's newsletter, Aaron Moncur has a conversation with Jon Lowy, a product engineer with over 40 years of experience in design and manufacturing, currently collaborating with Giga on DFM insights and technical writing.

Honestly, the best tool any engineer can ever hope to have exists and they just don't use it enough. It's your calipers and a pencil and paper.

In this episode:

Why the simplest engineering tools outperform complex software for understanding design problems

How refusing to compromise on bearing design at age 21 shaped a 40-year career philosophy

Why additive manufacturing remains prototyping rather than true manufacturing despite industry hype

How teaching high school transformed technical communication skills and made complex concepts accessible

Bonus Content:

The Start of my Annual Reset: Why "Leaders Eat Last" by Simon Sinek Remains Essential Reading

S6E11 Jon Lowy | Sleeping 3 Hours Per Day & Additive Manufacturing X.0

Jon Lowy built a machine 10 times faster than anything on the market at age 21, then got fired for refusing to remove a bearing. That moment set the tone for four decades of engineering work across robotics, oil drilling, sensor development, and manufacturing. His insights span from the tools engineers overlook - calipers and paper beat CAD for understanding problems - to why additive manufacturing remains 40 years away from matching traditional methods. He developed fruit storage sensors with 3-5 times better grading accuracy and learned that teaching teenagers how to control rage made him better at explaining manufacturing processes to investors. The conversation reveals how early technical decisions compound across careers and why the fundamentals still matter more than the latest technology.

>If YouTube isn’t your thing, check out this episode and all of our past episodes on Apple, Spotify, and all the rest.

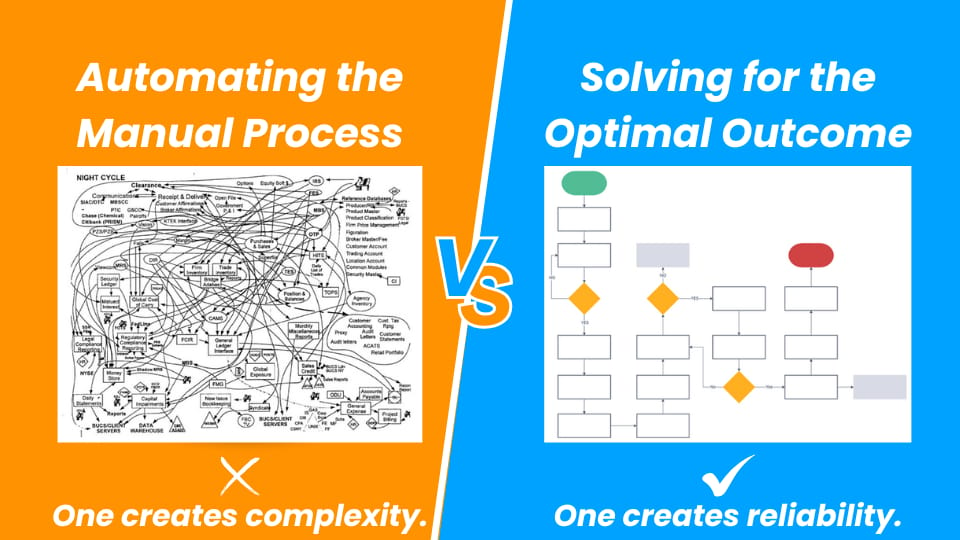

Stop. Before you automate that manual process step-by-step, read this.

In the 1890s, inventors tried to ease the transition from horses to automobiles by building "horseless carriages" - mechanical contraptions with articulated metal legs, rein-based steering, and fake horse heads housing lamps. They were solving the wrong problem. The answer wasn't replicating a horse. It was rethinking transportation entirely.

Modern automation projects make the same mistake. Your manual process evolved around human capabilities. Operators compensate for variation, use visual judgment, make micro-adjustments. Automating these workarounds directly creates complex, unreliable systems.

Pipeline Design & Engineering’s focus? Solving for the optimal outcome. Clear, reliable, effective.

Don't automate the workaround. Solve the actual problem.

Evaluating automation? Pipeline has solved this puzzle 100+ times.

Physical Tools vs Digital: Why Understanding Beats Automation

Jon's conviction about simple tools comes from decades of seeing engineers reach for software before understanding the problem.

Jon's conviction about simple tools comes from decades of seeing engineers reach for software before understanding the problem.

When he was commissioned to build medical sample processing robotics at 21, he designed around superfine aircraft cables with stationary motors. The pulleys carried significant, off-center loads that would destroy single bearings quickly. His CEO demanded cost reduction by switching to single bearings.

I said, 'No,' and he fired me.

The machine would have failed within hours. That early lesson reinforced that understanding load paths, bearing selection, and mechanical fundamentals matters more than hitting arbitrary cost targets. Measuring, sketching, and calculating forces reveals problems that 3D models can hide.

Understanding what's going on because you've evaluated it rather than looked at it.

The gap between evaluation and observation separates engineers who anticipate failures from those who discover them in testing. Calipers and calculations force that deeper engagement with the physics of a design.

The Start of my Annual Reset: Why "Leaders Eat Last" by Simon Sinek Remains Essential Reading

Every January I reread Simon Sinek's "Leaders Eat Last." as the start of my annual reset. I reread it because knowing leadership principles and practicing them under quarterly pressure are different challenges. The book grounds its arguments in biology: humans evolved to work in groups where survival depended on mutual protection. Modern workplaces optimize for individual achievement while starving employees of the trust that enables real performance.

For more, visit the full article on The Wave.

This Month’s Webinar Features: “Practical Project Management for Engineering Teams”

Mike Landis, Director of Engineering at Pipeline Design & Engineering, will share the actual project management framework Pipeline uses every day to manage dozens of concurrent engineering development projects, where budgets are significant, schedules matter, and scope creep can quickly derail outcomes.

A central focus of this webinar is a project budget and schedule tracking tool that Pipeline has refined (the Pipeline “Traveler”), iterated, and improved over literally decades of real-world use by multiple engineers across multiple companies. This is not a template pulled from a book or software tool - it is a battle-tested spreadsheet built specifically for the realities of engineering development work.

Used properly, this tool helps teams:

Proactively identify budget and schedule risk early, before problems become expensive

Detect scope creep as it happens, not after the damage is done

Make informed decisions sooner, allowing teams to pivot or course-correct

Maintain visibility into labor, material costs, and overall project health

For teams managing expensive engineering projects, the ability to surface issues early can easily save tens or hundreds of thousands of dollars. And in this session, Pipeline is simply giving this tool away.

Every attendee will receive a FREE copy of Pipeline’s Traveler spreadsheet, along with the context needed to understand how - and why - it works.